Substation Monitoring and Controlling Using IOT 2020

The distance between the generators and load may be regarding hundreds of miles hence the amount of enormous power exchange over long distances has turned out as a result of the lack of quality of the electric power.

Demanding the quality of power being delivered to the user side has raised the alarm due to the increase in demand for electricity on the customer side. A massive amount of energy is lost during the transportation of the general power which prompts the decrease in the nature of intensity got at the substation.

Substation Monitoring and Controlling Using IoT To improve the quality of power with a different solution, it is necessary to be familiar with what sort of constraint has occurred. The system might become unstable. Therefore it necessary a monitoring system that can detect and monitor. It plays an ever-growing role in our modern industrialized society.

Demanding the quantity of power being delivered at the user side has raised the alarm due to the increase in demand for electricity on the customer's side.A huge amount of power is lost during the transportation of the generated power which leads to a reduction in the quantity of power received at the substations. Also, the users of the electric line have identified that the number of drawbacks caused by electrical power quality variations is increasing rapidly.

What is Substation Monitoring System

Monitoring is the first step towards the implementation of the CBM strategy. basically of Monitoring consists of acquiring significant parameters from the assets. The collected data allow completing analyses and diagnose the condition of the assets which is of great use as a support to the decision-making maintenance schedule then, reducing failures and breakdowns.

A large amount of features to consider makes the Substation Monitoring complex. It can be both on-line (continuous) and off-line (discontinuous), or a combination of both, depending on the asset and the diagnosis to perform. Proper sensors data acquisition and software to process them are also needed. Moreover, substations are built with assets from different manufacturers the usual variety of communication protocols, too.

AIM OF Substation Monitoring System

Our aim is to provide a system that is user friendly and works to save manual labor, stop wastage of electricity, and use the lab equipment on the required power so that we can protect losses.

Objectives OF Substation Monitoring System

- To improve the quality of power remote sensing.

- Maintain Continuity of supply.

- Real-time monitoring.

- easy to use.

- protect your electrical appliances.

Advantages OF Substation Monitoring and Controlling Using IoT

- Wireless Monitoring System.

- Fast Control Action.

- Automatic Control Action.

- Accurate System.

- To protect the electrical circuitry by operating an SPDT relay

- To detect what sort of constraint has occurred

- To prevent the instability of the system

- To maintain continuity of supply.

Microcontroller Based System For Substation Monitoring

Thus, this is a simple and low-cost type of IoT-based project that helps students to get a basic idea about the substation automation. With this system, a user can control the substation’s equipment.

We have designed a system based on microcontroller atmel382p that monitors and controls the voltage, current, frequency, and oil temperature of a distribution transformer present in a substation. The monitored output will be displayed on the web.

The parameters monitoring at the distribution transformer are compared with the rated values of the transformer. Through the web, we can shut down the transformer so that it can be prevented from damages and Performances can be enhanced quiet to a remarkable level.

We have designed a system based on microcontroller atmel382p that monitors and controls the voltage, current, frequency, and oil temperature of a distribution transformer present in a substation. The monitored output will be displayed on the web.

The parameters monitoring at the distribution transformer are compared with the rated values of the transformer. Through the web, we can shut down the transformer so that it can be prevented from damages and Performances can be enhanced quiet to a remarkable level.

Working Functionality of Substation Monitoring and Controlling Using IoT

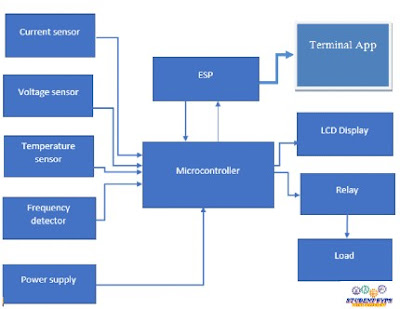

The Substation Monitoring and Controlling Using the IoT system are based on different types of sensors to measure the different electrical parameters. The sensors include ACS712 current sensor, AC voltage sensor, DHT (digital humidity and temperature) sensor, frequency sensor. All the sensors are interfaced with the microcontroller, the output of all the sensors is sent to the microcontroller which sends the real-time values of all the parameters to display on the LCD interfaced with the microcontroller.

The system is operated on 220v AC, a current sensor is connected in series with the mainline to measure the amount of total current consumed. Moreover, to measure the amount of current consumed by each line, three current sensors are used separately with each line.

A voltage sensor is connected in parallel with the mainline to measure the number of total voltages flowing throughout the system. A frequency (counter) sensor is used to count the number of current cycles per second. To measure the humidity and temperature within the substation a DHT is used, which operates on 5V DC. All the sensors consist up of semiconductor devices (transistor) which need a VCC (5V DC) to turn on, so a buck converter is used to provide VCC to all the sensors.

A voltage sensor is connected in parallel with the mainline to measure the number of total voltages flowing throughout the system. A frequency (counter) sensor is used to count the number of current cycles per second. To measure the humidity and temperature within the substation a DHT is used, which operates on 5V DC. All the sensors consist up of semiconductor devices (transistor) which need a VCC (5V DC) to turn on, so a buck converter is used to provide VCC to all the sensors.

A microcontroller is used which is powered through a 12V adapter. The output of all the sensors is connected to the microcontroller and the microcontroller sends this value to display on LCD in a serial way. The microcontroller is programmed and interfaced with an ESP module (a Wi-Fi module). The ESP module is connected with the systems which receive the data, the real-time value of all electrical perimeters, form the microcontroller, and sends this value through the internet to the mobile device or PC connected with the same network.

It also receives control command form the device and transmits then to the microcontrollers which decide the action to do w.r.t the commands and the microcontroller then executes these commands by switching the ON\OFF the relays, which control the load.

Flow Chart Of Substation Monitoring and Controlling Using IoT

Block Diagram

Comprehensive Schematic Diagram

Hardware list Components

1. ESP Module 12. Microcontroller 1

3. LCD 20x4 1

4. Transformers 3

5. Relay Board 1

6. Current Sensors 4

7. Voltage Sensors 1

8. Temperature Sensor 1

9. Frequency Sensor 1

10 Buck Converter 1

11 Snubber Circuit 1

13. Connecting Wires

14. Breaker 1

15. Load Inductive + Resistive

SYSTEM LIMITATIONS

Every electrical/electronic system is a result of a series or parallel connecting electronics components, and every component has a specific operating range as well as their unique characteristics. The limitation includes the operating current and voltage range of components, the power consumption by each component, the suitable environment, proper connections, and proper monitoring techniques.